The Official Saucisse Aux Choux Vaudoise IGP

Name: Saucisse aux choux vaudoise

Region: Vaud

History: The origin story of the saucisse aux choux vaudoise has its roots in legend. It’s said that the saucisse owes its invention to the town of Orbe during the middle ages, around the year 879. The Emperor Charles the Fat was supposedly in town overstaying his welcome, and eating the town out of house and home. As meat became rare, an innovative townsperson had the brilliant idea to use cabbage to make their sausage in order to stretch the meat. Now, it could just be that this was a commonplace thing, to stretch meat with whatever was around, but who doesn’t like a compelling story? It became a regional specialty, made to this day, and protected under PGI identification.

How it’s made:

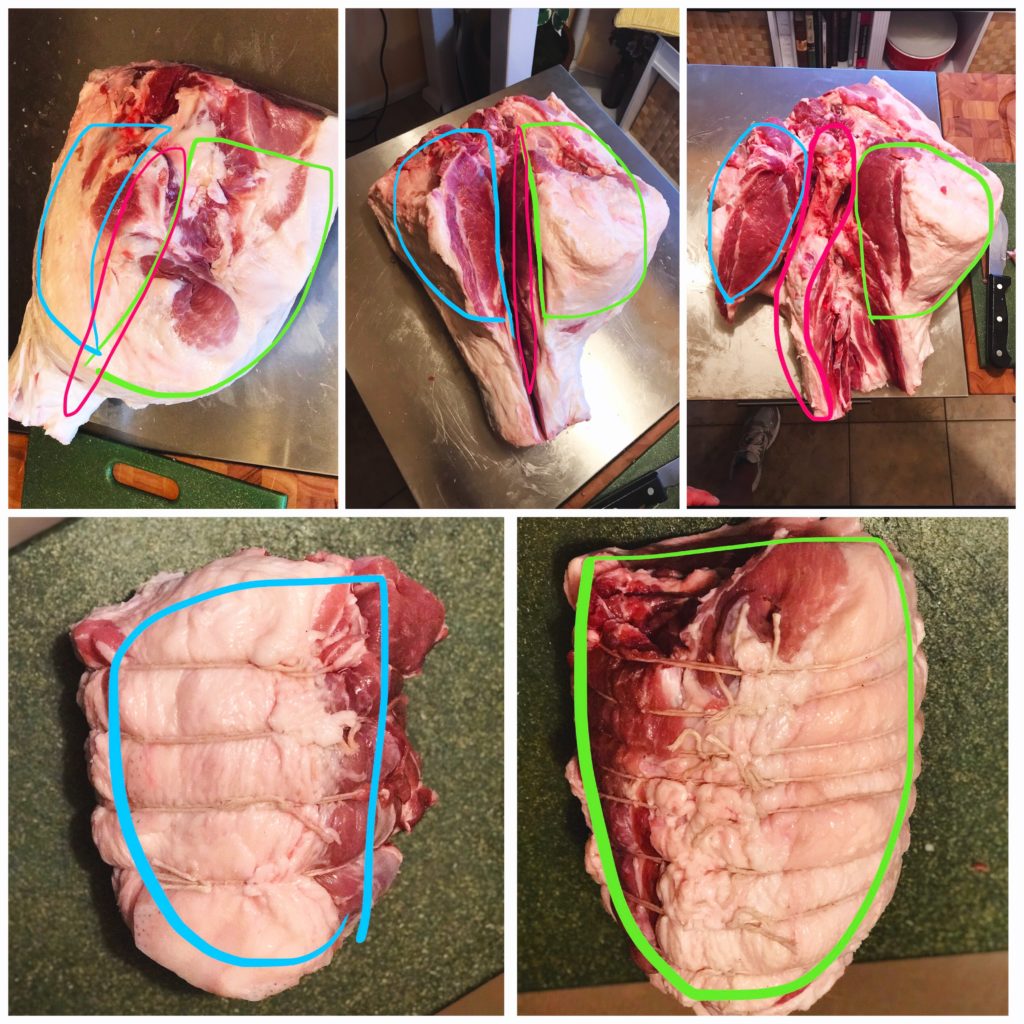

Meat: A 60% lean pork meat to 40% pork fat ratio. Boiled pork skin (~25%), blanched and pressed white cabbage(~5%). Optional: Pork liver (~5%).

Note: The meat is a combination of pork 1 and pork 2 with minimal membranes, sinews, or tendons. See Charcutier, Salumiere, Wurstmeister by Francois Vecchio to get a better understanding of the pork 1 and pork 2 breakdown.

Spices: Salt, black pepper. Optional Spices: Garlic, coriander, nutmeg, mace, cloves, and anise. Other optional components: White wine, sugar, nitrates, starter culture.

Processing: Lean pork mixed with fat and skin is used for this saucisse. The meat is ground using a 5 mm plate, while the boiled pork skin is ground through a 3 mm plate. The meat is mixed with the spices until it has achieved a good bind. Then, this mixture is stuffed into beef casings with a diameter of 38-40 mm or 40-42 mm, looped, with a length of ~ 30 cm. The ends can be tied off with either string or clips. Each sausage should weight around 300-400 g. It is then hung and cold smoked (18-28 C) for 24 hours, usually using a mix of local hardwood and conifer. The cold smoke gives the exterior a golden brown exterior, while the inside remains a nice reddish pink color.

Timing: Like most cured meat products, this one is made during the colder months, traditionally between September and April.

How it’s eaten:

After the meat has been smoked, it’s ready to be cooked and eaten. The saucisse is usually boiled for 35-40 minutes at ~ 75C, before being cut open and served on a bed of leeks and potatoes (called papet Vaudois). Some chefs prefer not to cook the sausage separately, but cook the sausages over low heat directly on the papet Vaudois. If you’ve made this sausage (or if you’ve bought it) and want to eat it in the traditional way, I suggest checking out this recipe by Helvetic Kitchen.

How I learnt about it:

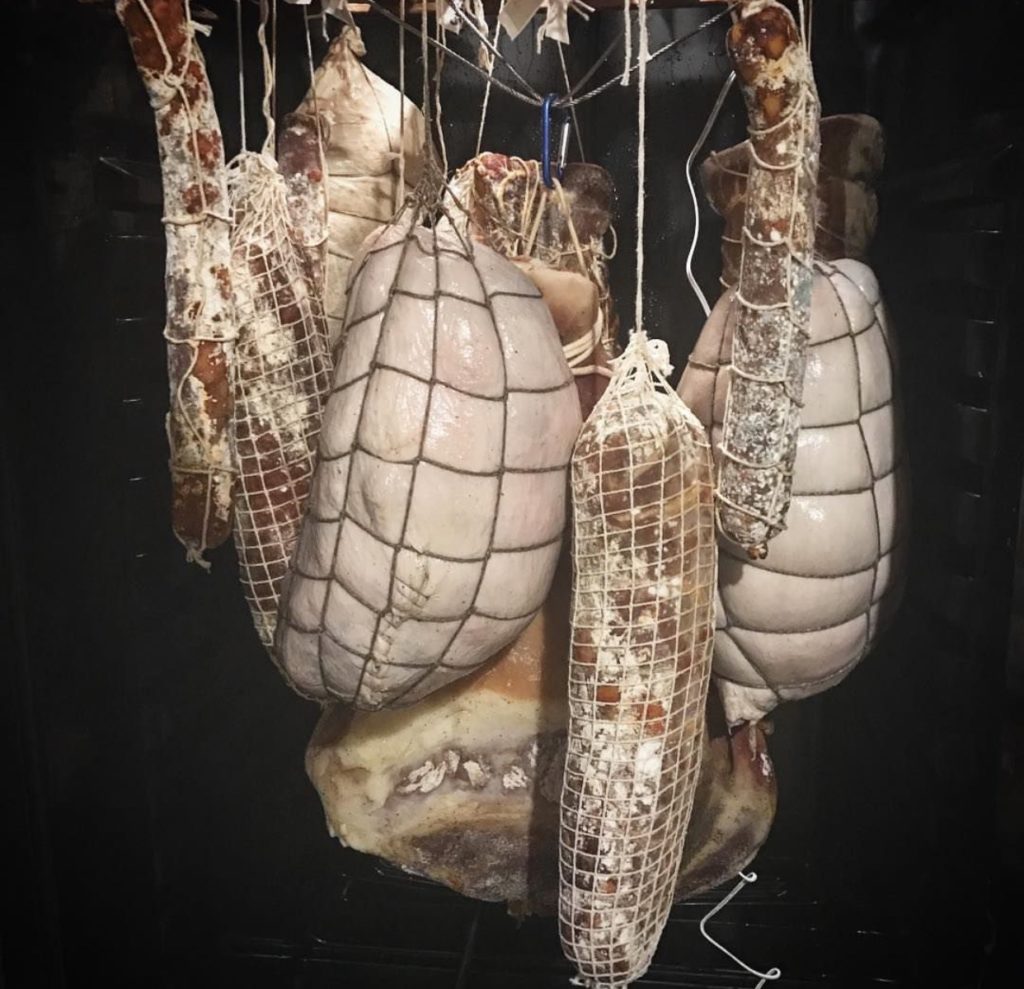

This is arguably the least interesting for those out there who are reading this on order to create their own projects, but hopefully of some interest to those who (like me) are interested in traveling the world chasing cured meat. This wurst is an IGP product from the Vaud region of Switzerland, and in particular, its birthplace is said to be in the town of Orbe. Therefore, for a number of years now, the town of Orbe has held a three-day festival on the last weekend in September to celebrate this product. The festival is filled with local food, beer, music, and of course, a demonstration of the local butchers making the sausage itself!

This year, I took the time to travel to this festival, where I was able to see the sausage being made, communicate (in very broken French that was probably actually more Italian than French) with the butchers doing the demonstration about the process, and sample the sausage in the traditional manner.

The DIY Saucisse Aux Choux Vaudoise IGP

Now, it’s not really saucisse aux choux vaudoise unless it’s made in the region of Switzerland discussed above, in the manner discussed above, with Swiss ingredients. However, that doesn’t mean you can’t make it at home and call it whatever you want. Here, I’ll post the recipe how I would make it at home.

Disclaimer: Unlike all my other recipes, I haven’t actually made this one at home yet, so there won’t be any process pictures to follow. Hopefully, I will find the time to make it myself soon, and then will update this page.

Planning:

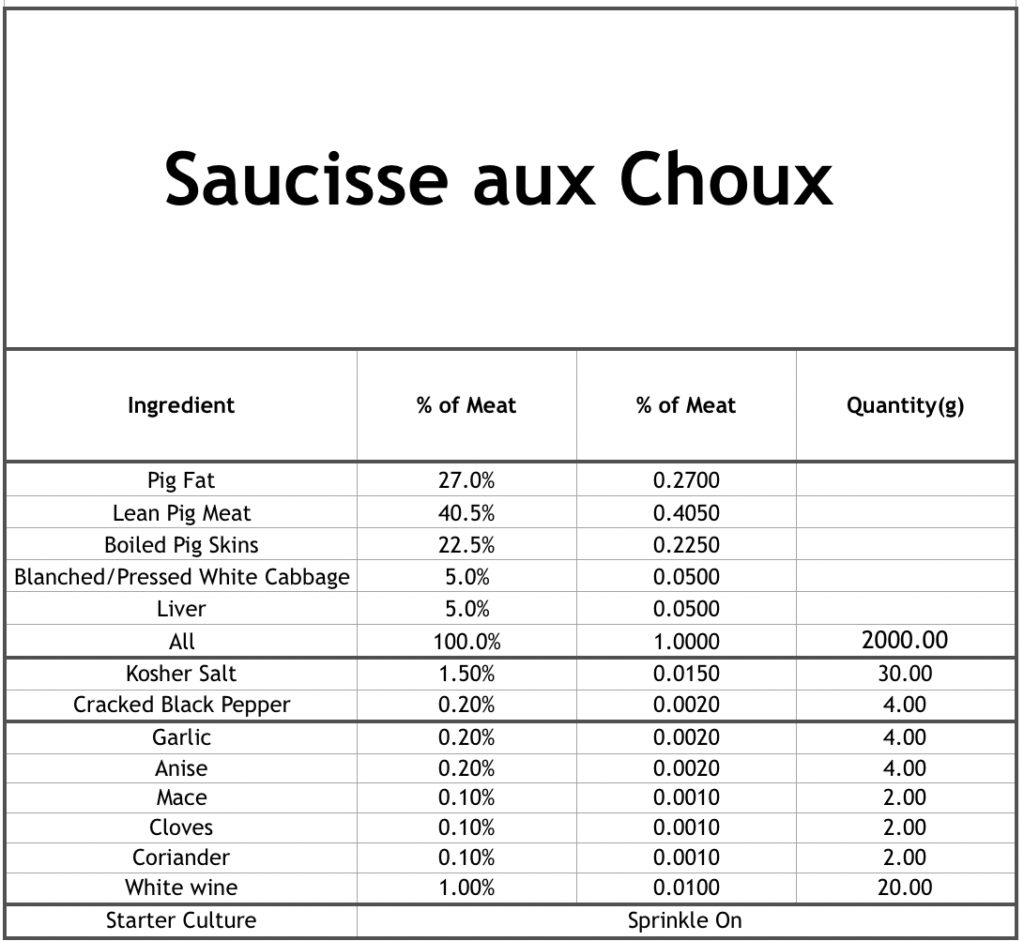

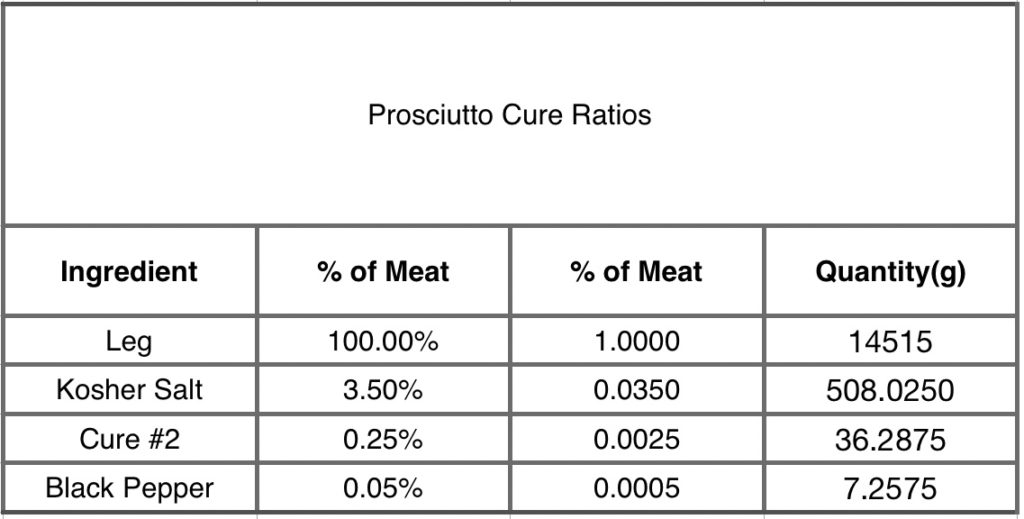

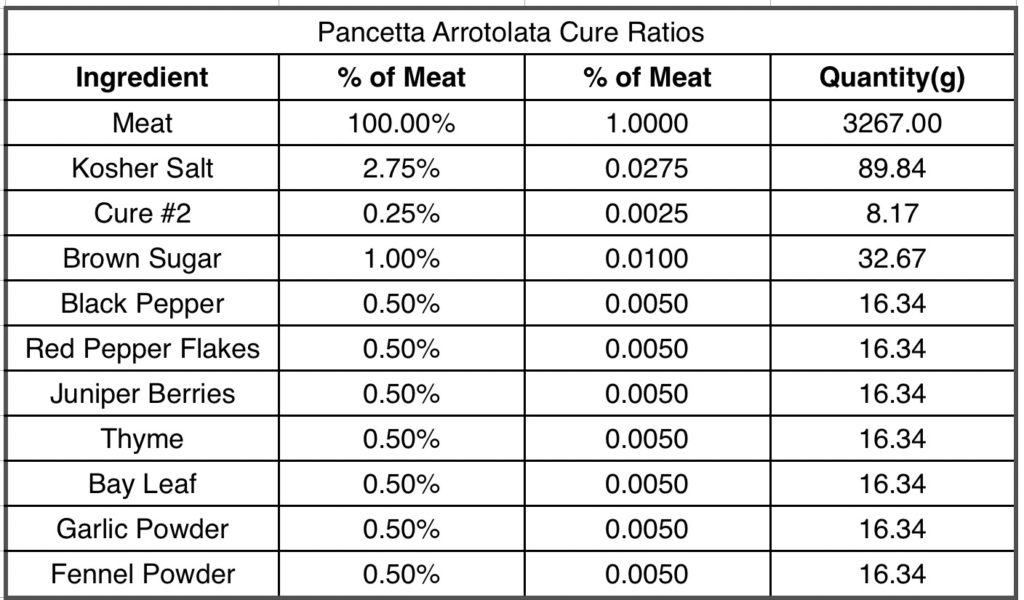

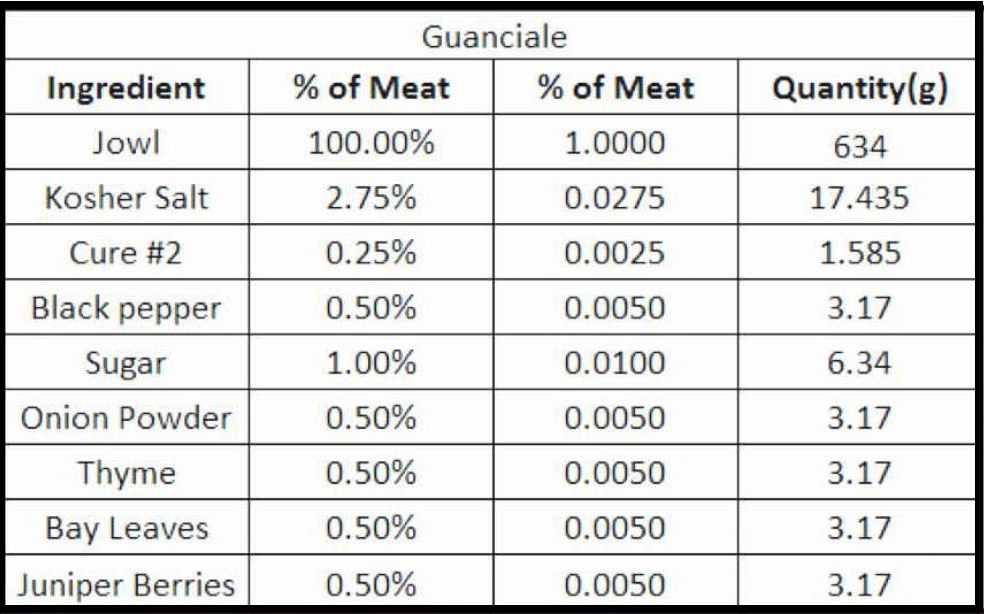

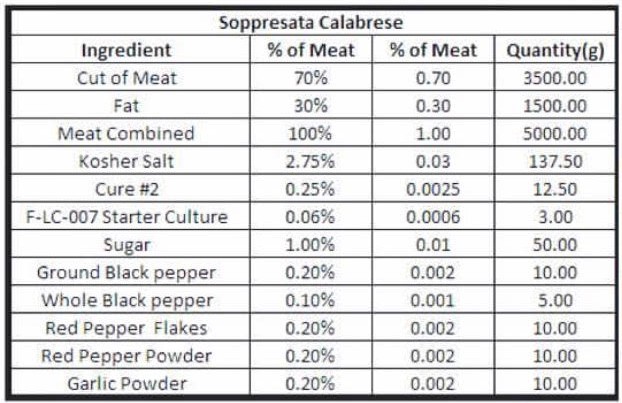

The following spreadsheet gives an approximation of the ratios to use for this saucisse, of course amounts and spices can be altered for taste.

Grinding and Mixing:

Grind the meat, fat, blanched and pressed cabbage, and liver through a 5 mm plate. Grind boiled pig skins through a 3 mm plate. Mix them together with the white wine and spices until you create a paste that sticks together with a nice consistency. Keep it cool while you do this.

Stuffing:

Take the mixture and stuff it into casings, preferably Beef Rounds (40/43 mm). You can usually find these already cut and tied. Make sure to stuff the mixture in a steady and compact manner. Tie off the ends.

Fermentation/Cold Smoking:

Once the saucisse is stuffed, tie the two ends together, and hang it in a place where you have a cold smoking set up. Preferably, cold smoke using hard wood for around 24 hours. Keep the temperature below 82 F. At this point, you’re almost ready to go.

Enjoying:

To enjoy this saucisse, boil it for 35-40 minutes at ~ 75C, cut open, and served on a bed of leeks and potatoes or use the recipe from Helvetic Kitchen mentioned above.

Sources:

http://www.charcuterie-vaudoise.ch/sites/default/files/Saucisson_VD_2019.pdf

http://www.charcuterie-vaudoise.ch/fr

https://www.patrimoineculinaire.ch/Produit/Saucisse-aux-choux-vaudoise-IGP/78

https://www.aop-igp.ch/index.php?id=305&L=1

https://www.helvetickitchen.com/recipes/2016/3/3/papetvaudois

Disclaimer: Meat curing is a hobby that comes with inherent risks. We can all do things to limit this risk by educating ourselves about the process and the utilizing the safest known methods to create our products. This website is for educational purposes only, and all experimentation should be done at each individuals own risk.