Name: Mostbröckli

Region: Appenzell

History: Mostbröckli is a smoked and dry cured meat product made from beef in the Appenzeller region of Switzerland. Historically, the Appenzeller farmers were very active in the dairy industry, which accounts for the use for beef to make this product as opposed to the more expensive (at the time) pork. It is thought that it name comes from the fact that it is either cured with or enjoyed with “most”, fermented apple wine commonly called cider in English, Suure Moscht in Swiss German, or Apfelwein in high German.

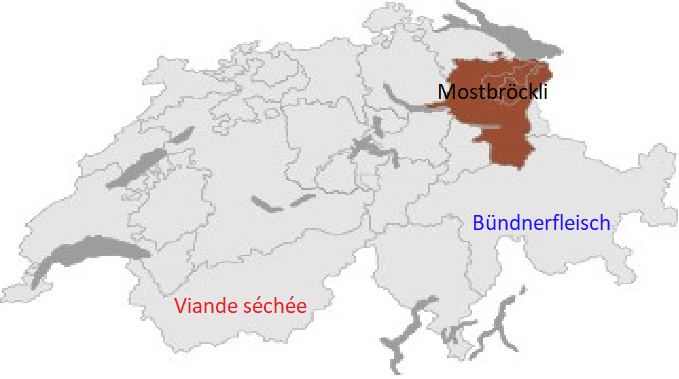

It is one of three famous beef cured products in Switzerland. The other two are Bündnerfleisch from Graubünden and Viande séchée (also known as Trockenfleisch in the German-speaking parts of Switzerland) du Valais. However, Mostbröckli is the only one of the three that is smoked. And while Bündnerfleisch is characteristically always pressed into a rectangular shape, as is Viande séchée, Mostbröckli can be netted and shaped but does not need to be. This is due to regional differences where these cured meat products were developed. Graubünden and Valais both are mountainous regions and air-drying can naturally be carried out in the alpine air from 800-1300 meters above sea level. Appenzell is a more humid low-lying valley, where the traditional drying relied upon smoking in order to preserve meat. The process for drying Mostbröckli takes on average 5 weeks, while for Viande séchée it takes 5-16 weeks, and for Bündnerfleisch it takes 12-24 weeks…of course all dependent on size and environmental conditions. So now that we have a bit of an understanding of the geographic conditions that shaped the process of curing, drying, and smoking Mostbröckli in Switzerland, how is it made?

How it’s made:

The meat:

These days, Mostbröckli is made with beef (although it was traditionally also made from horse and dog meat) from one of the following cuts:

Runder Mocken

Eckstück

Vorschlag

Nierstück

Huft

I personally like to use the same cut I would use for bresaola, the eye round cut, which is easy enough to find from butchers in the US.

The spices:

- Mandatory Spices: Sea salt, sugar, black pepper, bay leaf, juniper, and garlic.

- Additives: Nitrates and anti-oxidants (to prevent against oxidation of fat, especially in projects with beef, there is the traditional industry use of ascorbic acid or sodium ascorbate. For personal projects, I haven’t found them to be much use.)

- Optional Spices: Other spices such as allspice can be added as long as they do not overpower the mandatory ones.

- Optimal Liquids: Wine or “most”.

- Optional Additions: MSG, potassium sorbate, and whole muscle starter cultures such as Lactobacillus species, food-grade Staphylococcus species, or Micrococcus species.

The Processing:

Similar to bresaola, because this is beef and beef fat tends to oxidize faster than pork fat, the raw meat is stripped of fat and tendons. (This is done traditionally in the industry for beef products, but I’ve done some very nice projects with fatty cuts of beef with no issues, so we’ll do it here for traditions sake, but know that it’s not as hard and fast rule as some would lead you to believe.)

The meat is rubbed with the spices mentioned above and allowed to dry cure. They can either be cured in a traditional excess cured way, or using equilibrium curing under vacuum. Depending on the size and the method, the curing process can take anywhere 1-5 weeks. I will do this step using equilibrium curing under vacuum.

After curing, the meat can be hung in a cold place for 1-4 days. If using a preservative such as potassium sorbate to prevent unfavorable mold development, it can be added here. I will personally skip this step when making it at home.

The meat then hung in a smokehouse set up, where it is smoked over the time period of 1-3 weeks. In this stage, the temperature can reach up to 40C, which is higher than most other cold smoked products. This accelerates the weight loss for this particular type of cured meat product. The final weight loss should be between 30-45%, and will take 1-3 weeks. Various woods are allowed to be used to generate the smoke for this process.

Timing: Like most cured meat projects, it is traditionally cured throughout the wintertime after the fall harvest.

How it’s eaten: Appenzeller Mostbröckli should be enjoyed thinly sliced, served with a piece of dark bread, such as a Bürli. Given its name, it can be enjoyed with a nice Suure Moscht. Ideally suited for a summer apéro along the river with friends.

How I learnt about it: Traveling around Switzerland, I’ve run into Mostbröckli, Bündnerfleisch, and Trockenfleisch and wondered what set them apart. I made sure to buy all three to bring to a summer apéro with friends to determine the differences between them and pick my favorite.

(Un)fortunately, we ended up rafting down the Limmat river, and our apéro ended up being a picnic along the bank of the river until the sun set, with enough Swiss beer that while I know I had a favorite, for the life of me I can’t remember which it was. All it means is I need to re-try them all again soon!

The DIY: I haven’t made this one yet, but it is high on my list of next projects. Because of that, I’ve made a curing sheet recipe that is attached here. Just be aware, this is currently an untested recipe.

Curing:

Weigh your eye round of beef or whichever cut you have decided to use. You can use the following interactive spreadsheets to calculate the cure you will need for your own project; just fill in the weight of your meat in the appropriate white cell in the spreadsheet and hit enter. There is no need to make any other changes to the spreadsheet.

*Note: Please use common sense. Make sure the spreadsheet is working properly for you and double check any calculations that don’t seem right.

Mix the meat together with the spices, vacuum seal it together, and allow it to cure at 4C for 2-3 weeks.

Casing:

After this time, rinse off the cure. If you would like, rinse the meat in “most” aka cider for 30 minutes or so, to give it some extra flavor. You could continue this overnight if you wanted a stronger flavor from the cider.

I prefer to case my cured meat products, because I feel that it promotes more even drying and results in a better end product. This is optional, but if you would like to, now is the time to case the meat in a beef bung, tie it up, and hang it in a curing chamber at around 12C, 75% RH for 4 days.

Smoking and Drying:

If you have a smoke house, after 4 days move it to the smokehouse to be smoked and dry cured altogether in the more traditional manner. In this way, it should be ready at ~30-45% weight loss in about 1-3 weeks. Make sure that temperatures don’t exceed 40C.

Otherwise, we will do stepwise smoking. In this method, move the meat from your dry curing set up as frequently as possible to your cold smoking set up. This will be highly dependent on your set up and time availability. For example, you might move it to your cold smoking every set up every weekend to cold smoke it for 8 hours, and then return it to your dry curing chamber after the cold smoking is complete for another week. In this way, you can infuse the meat with smoke while still maintaining it at the safe temperature and humidity conditions it needs to lose weight over time. With this method it may take longer to meet the target weight loss of 30-45%. It won’t be the traditional method, but with some flexibility and by keeping an eye on it, you can approximate it pretty well at home.

Tasting:

After it has reached its target weight, you can clean off any mold with more “most” or cider. Make sure to slice it thin, and enjoy!

Disclaimer: Meat curing is a hobby that comes with inherent risks. We can all do things to limit this risk by educating ourselves about the process and the utilizing the safest known methods to create our products. This website is for educational purposes only, and all experimentation should be done at each individuals own risk.

References:

https://www.patrimoineculinaire.ch/Produkt/Bundnerfleisch-GGAIGP-Pulpa/342

https://www.aop-igp.ch/appenzeller-mostbroeckli/

https://www.patrimoineculinaire.ch/Produit/Viande-sechee-du-Valais-IGP/120

Leave a Reply