Mosciame. Mojama. Muxama. That seductive, yet elusive charcuterie product that I have been trying so hard to recreate. The taste of which transports you to sunlight days, with sea salt breezes, where nothing ever seems to be urgent, pressing, or stressful. The pace of modern day life seems to be slowed down by simply a taste of this delicious cured product. Obviously, once the idea of recreating this transportive taste took hold of me, I couldn’t rest until it was done satisfactorily. And finally, I can rest, happy with the success of the process that I will detail here.

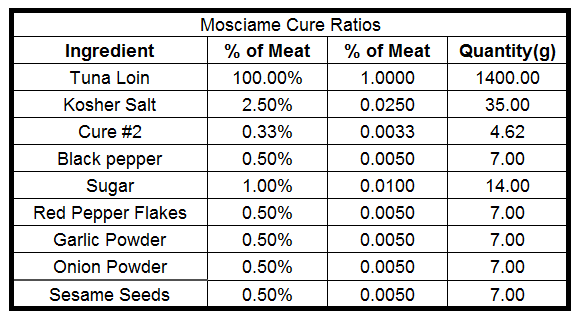

In this post, I will detail my second attempt at making modern style mosciame. You can read about my first attempt at making modern mosciame here. After my first attempt at making modern style mosciame yielded such a strong flavored product, I decided to try to make one that was milder and had more universal appeal. In order to do this, I limited steps that I thought may have increased its strong and earthy flavor. I didn’t use a starter culture in the cure, I used cheesecloth instead of a beef bung for casing, I lowered my RH to 70%, and my temperature to 50 F in order to stimulate more rapid weight loss and to discourage excessive mold growth.

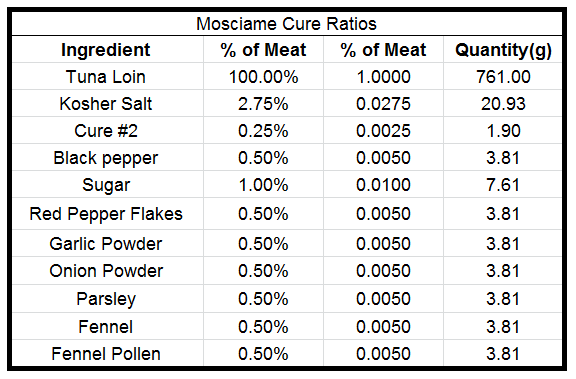

Curing (2 weeks):

The meat was cured using an equilibrium cure for 2 weeks in the normal refrigerator.

After this point, the cure was rinsed off and it was patted dry.

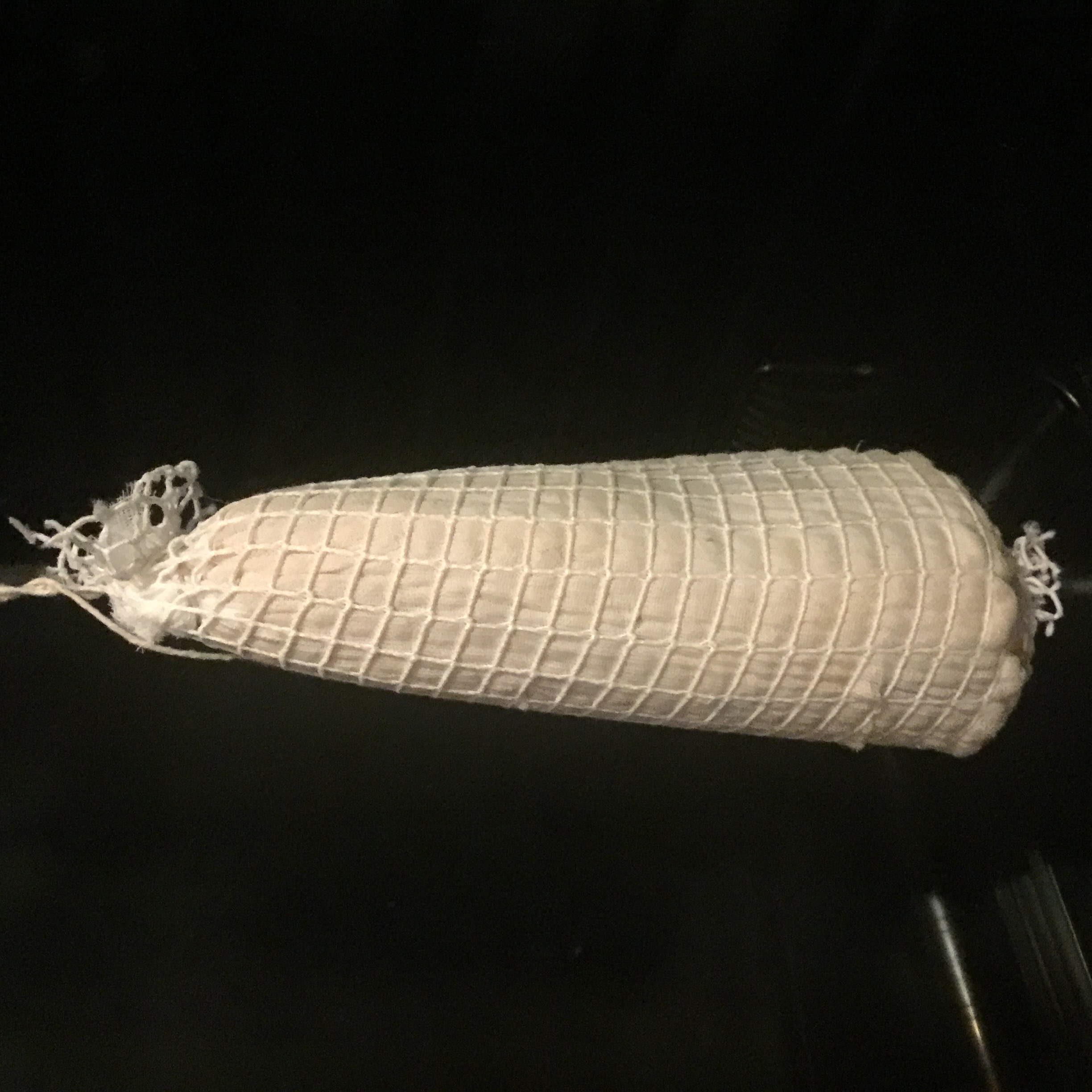

Casing (1 hour):

The tuna was then cased using cheesecloth.

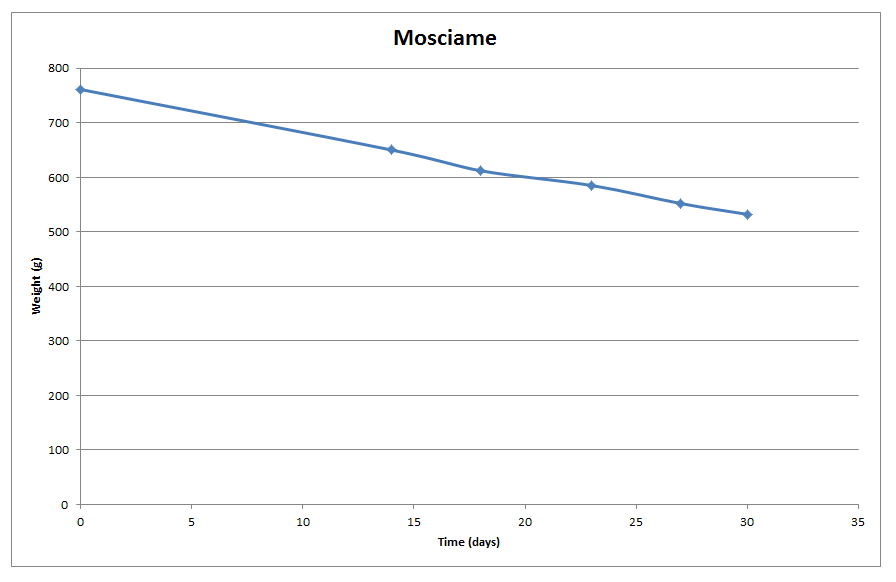

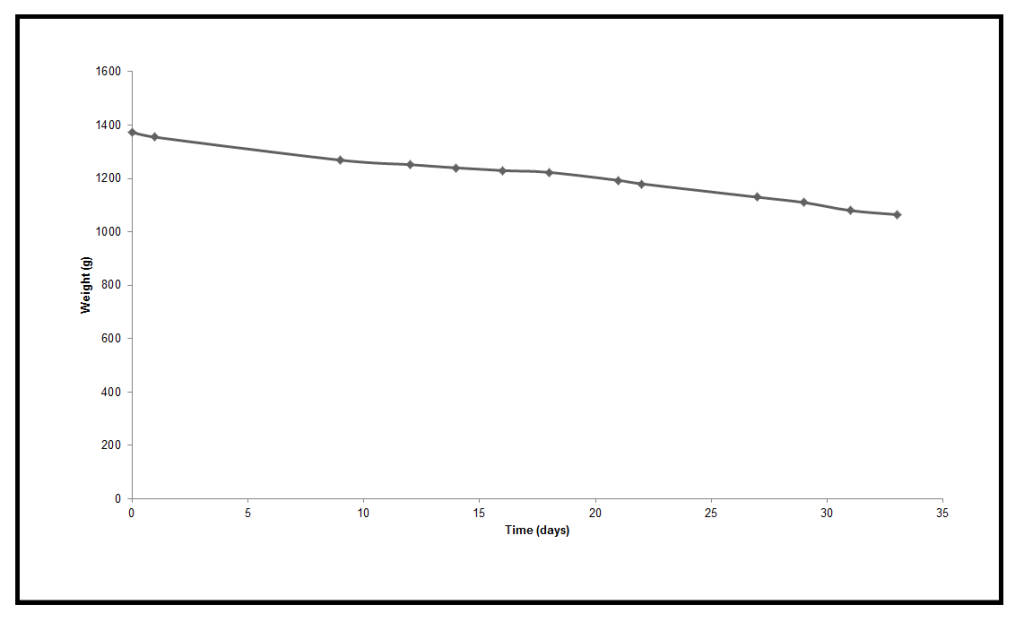

Drying (1 month+, until 30% of weight is lost):

Temperature: 50F/10C, Humidity: 70% RH

It was hung in the curing chamber in order to dry.

After 30 days, it had lost 30% of its weight and was pulled from the curing chamber.

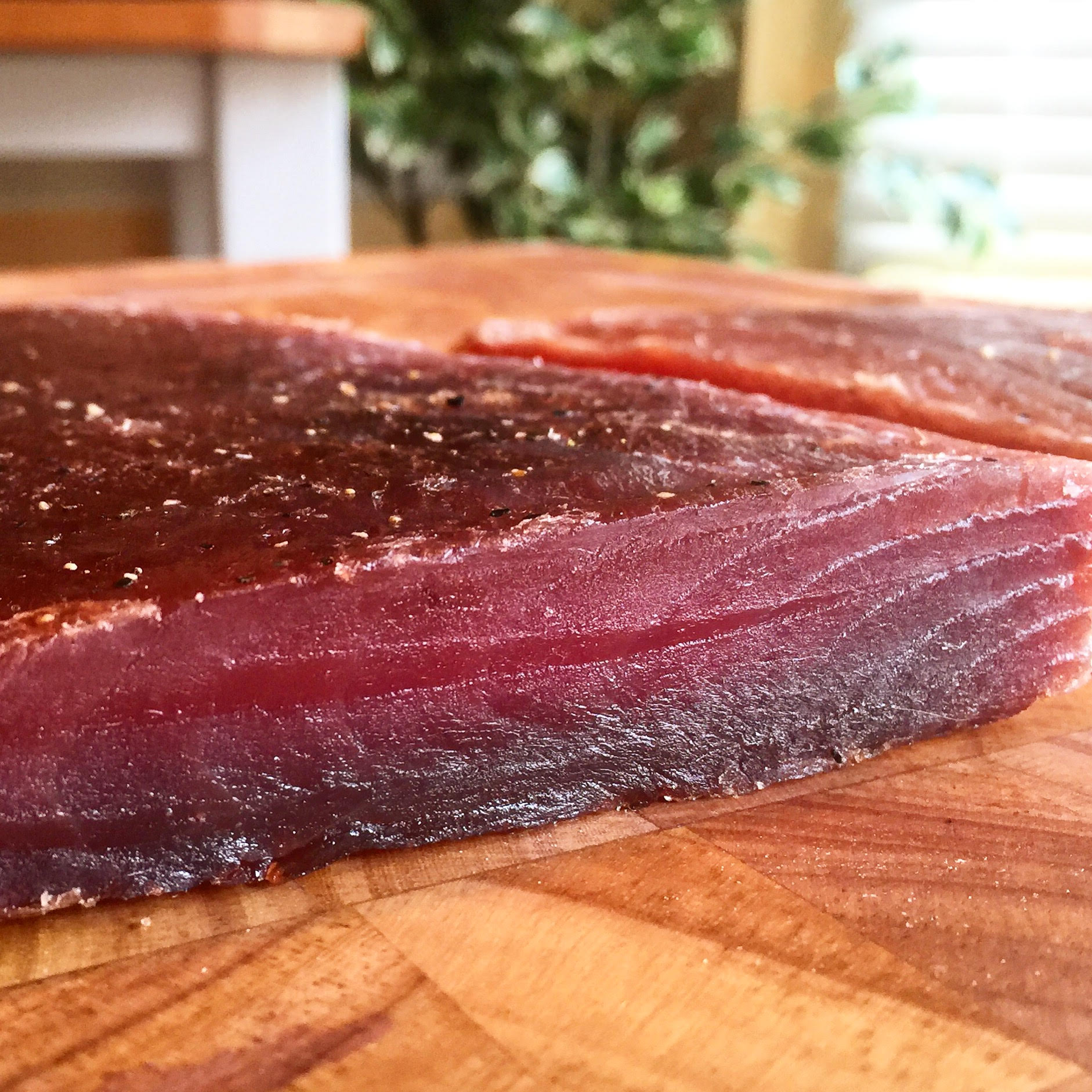

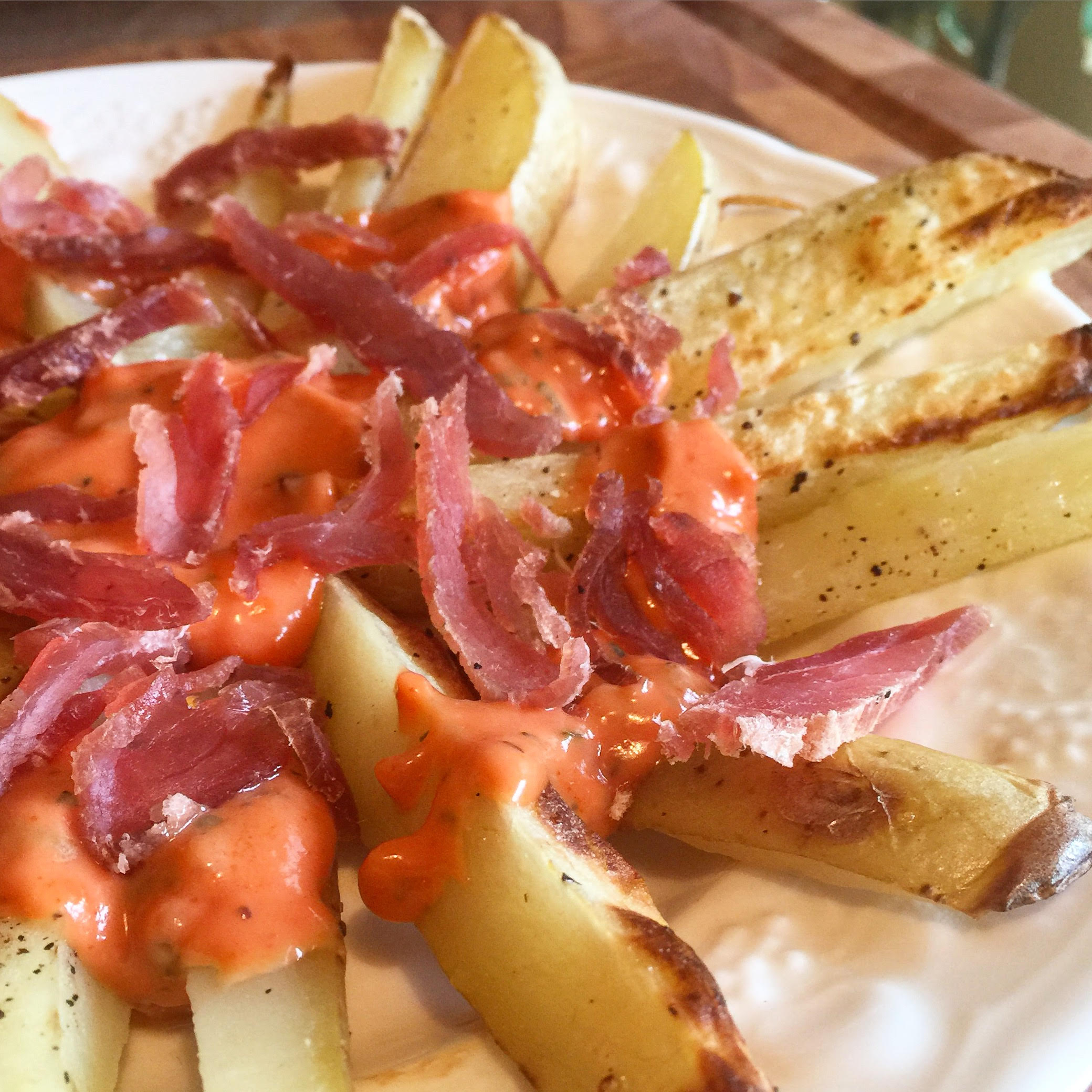

Tasting:

The mosciame was taken out of its casing, scrubbed clean with white vinegar, and patted dry.

I was excited to try this, and boy oh boy, I was not disappointed.

This mosciame has the complex umami flavor you’d expect of aged tuna, without some of the stronger more yeasty overtones that the first modern mosciame trial had. It seems like one or more of the changes that I made in my protocol made this process work a bit more traditionally and created a product with more universal appeal.

Sliced thin with my cuchillo jamonero, or my jamón carving knife, this product is amazing.

It is always nice when one of your experiments works! While I will still sneak slices of my first modern mosciame trial for myself as a treat, I have a feeling that I will be slicing this second modern mosciame product more often for friends and family.

Stored under vacuum seal for future uses!

Disclaimer: Curing fish is a hobby that comes with inherent risks. We can all do things to limit this risk by educating ourselves about the process and the utilizing the safest known methods to create our products. This website is for educational purposes only, and all experimentation should be done at each individuals own risk.