I have made bresaola in a number of different ways since my first bresaola experiment and learned tons. I have made more bresaola in the original way described in most charcuterie books. I have made bresaola using a traditional Italian recipe that utilizes red wine that was detailed to me by an Italian friend who has been doing this for ages. I have experimented with unique spice cures. And I have also used different cuts of beef to make new types of bresaola. Here, I will update my traditional bresaola process. Future posts will details some of the variations that I have tried.

Curing (2 weeks):

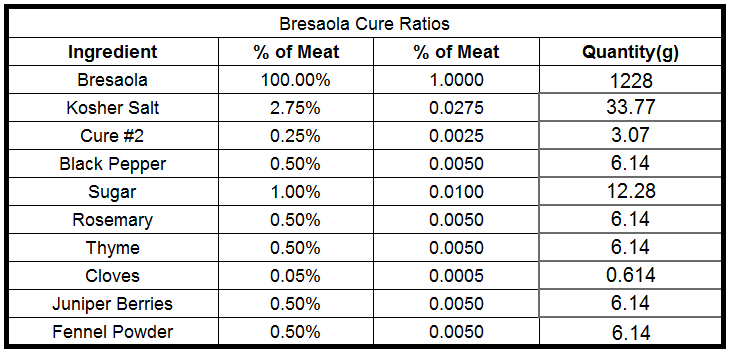

I have updated my curing ratios in the past few years based off of my experience, research, and discussions with other people who cure their own meat. These ratios reflect my personal preferences and can be changed according to taste, but the salt and cure #2 represent a minimum value, and less should not be used. The cure was rubbed onto the meat, and vacuum sealed. It was allowed to cure in the fridge for two weeks.

Casing (1 hour):

Beef bungs are my casing of choice for bresaola when I have them on hand. Sometimes, it’s time to case the meat, and I realize I am out. In these times, I use collagen casings. If I’m out of both of these, cheesecloth will work. In this case, I used beef bungs. I soak them in water before using them to allow them to stretch out before using them to case the bresaola.

After the bresaola was cased, a toothpick was used to puncture any air holes that may have been evident and could harbor the growth of bad bacteria.

Sometimes, I spray my meat with Bactoferm Mold 600, which is a single strain culture that contains freeze-dried form spores of Penicillium nalgiovense. This promotes beneficial mold growth and tends to keep any potentially dangerous mold growths at bay. However, after years of using a curing chamber, the chamber itself will tend to become inoculated with the mold culture itself, making spraying the meat directly less necessary.

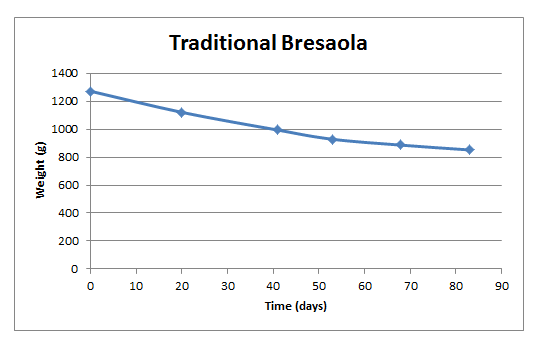

Drying (1 month+, until 30% of weight is lost):

Temperature: 54F/12C, Humidity: 70-80% RH

The bresaola was put directly into the curing chamber at this point. If you have read my first bresaola post, you know that I used to use a fermentation stage step. I have found this to be unnecessary for whole muscle cured products, and now move directly from the curing and casing stages to the drying stage.

The meat was allowed to lose ~30% of its initial weight, and was pulled from the chamber.

Tasting:

Ahhh….the taste of a home cured bresaola, tender and flavorful never gets old.

Disclaimer: Meat curing is a hobby that comes with inherent risks. We can all do things to limit this risk by educating ourselves about the process and the utilizing the safest known methods to create our products. This website is for educational purposes only, and all experimentation should be done at each individuals own risk.

I love ur post how do I find other recipes of meats u have cured ?

Thanks! Check out my IG, I often post recipes there before I type up the blog post.

Love this post I would love to learn ur red wine process where could I find that artical?

I’ve been doing an adapted version of the red wine process lately. Basically I will do the regular dry cure. When its time is up for the dry curing phase, I will rinse it off and add red wine to the vacuum bag and seal it and let it soak overnight. I find this gives it a good flavor without changing the texture too much.